|

Written by Liz McDermott |

The Globally Harmonized System (GHS) Workplace Hazardous Materials Information System (WHMIS) has several vital purposes and benefits for communicating hazard information about hazardous products.

Firstly, GHS enhances the protection of workers by providing consistent hazard information on hazardous chemicals, allowing individuals to make informed decisions when using or handling hazardous materials. Secondly, this harmonized system of classification facilitates international trade by providing a common language for chemical hazard communication. Lastly, it promotes the safe handling, storage, and transport of chemicals, minimizing the risk of accidents, injuries, and environmental damage.

This article covers GHS implementation under Canada's Workplace Hazardous Materials Information System.

TABLE OF CONTENTS:

- What is the Globally Harmonized System (GHS)?

- What changed with WHMIS 2015?

- GHS and WHMIS 2015: Similarities and Differences

- GHS Symbols and Their Meanings

- GHS Hazard Classes and Categories

- GHS Criteria For The Different Hazard Classes

- GHS Labelling Requirements

- Safety Data Sheets (SDS) and Their Importance

- What are the suppliers' duties under GHS?

- What happens when an inspector visits the workplace?

- GHS Resources and Tools

What is the Globally Harmonized System (GHS)?

The Globally Harmonized System (GHS) is an internationally recognized system for classifying and labeling chemicals. The United Nations developed it to provide a standardized approach to chemical classification, labeling, and hazard communication worldwide. The GHS aims to ensure the safe use, handling, storage, and transport of chemicals by providing consistent information on their risks.

How does a country adopt GHS?

When a country decides to adopt the GHS, it must incorporate the GHS elements into its existing chemical regulations or develop new rules that align with the GHS. The adoption process usually involves thoroughly reviewing the country's current regulations and identifying gaps or inconsistencies with the GHS. The government then updates its rules to align with the GHS, considering its unique legal framework and specific industry needs.

When a country adopts GHS, must all GHS elements be adopted?

While adopting the GHS requires countries to incorporate the system's core elements, such as hazard classification, labeling physical hazard criteria, and safety data sheets (SDS), governments have some flexibility in implementing the GHS. They can adopt additional elements or modify certain aspects of the system to suit their specific needs. However, the overarching goal is to ensure consistency in hazard communication across borders.

Who enforces GHS?

The enforcement of hazardous products regulations varies from country to country. Some regulatory agencies enforce GHS requirements, conduct inspections, and impose penalties for non-compliance. In other countries, industry associations or trade unions may play a role in ensuring compliance. Businesses need to understand the regulatory framework in their country and comply with the relevant enforcement agencies to maintain a safe working environment.

What changed with WHMIS 2015?

Canada's Workplace Hazardous Materials Information System (WHMIS) was updated to align with the GHS. In 2015, the new hazard classes, categories, pictograms, and changes to labeling requirements for health and safety information and data sheets were integrated —the update aimed to improve hazard communication and ensure the safe use of hazardous materials in Canadian workplaces under WHMIS 2015.

GHS and WHMIS 2015: Similarities and Differences

While GHS and WHMIS 2015 share the goal of ensuring the safe use and handling of hazardous products, there are some notable similarities and differences between the two systems. Both systems use hazard classification, labeling, and safety data sheets to communicate chemical hazards. However, WHMIS 2015 has additional requirements specific to the Canadian context of workplace chemicals, such as bilingual labels and unique WHMIS symbols. Businesses operating in Canada must understand and comply with WHMIS 2015 requirements to maintain GHS compliance and protect the health and safety of their workers.

GHS Symbols and Their Meanings

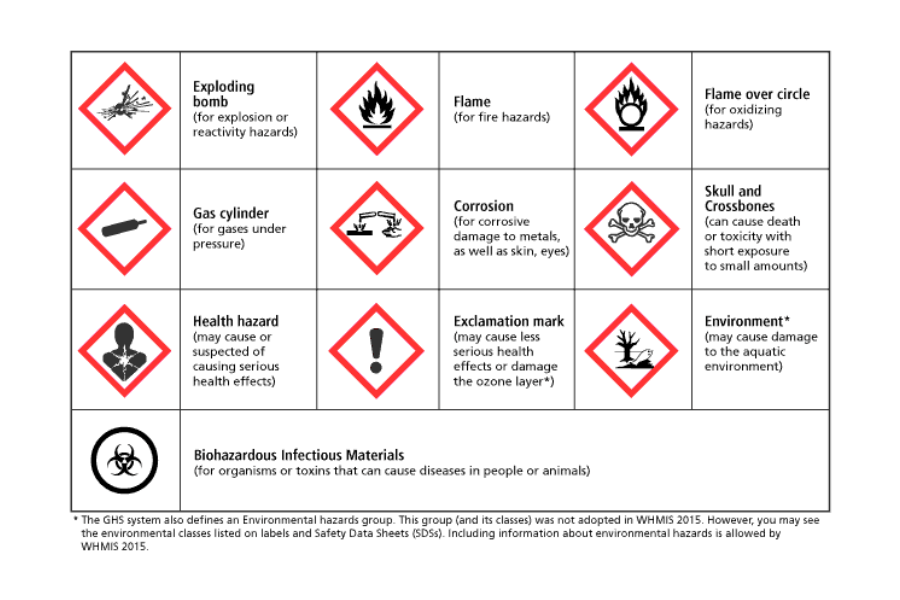

GHS symbols, or pictograms, are standardized graphical representations of different hazards. These symbols are used on labels and safety data sheets to communicate the specific risks associated with a hazardous product visually. Each symbol represents another hazard class, such environmental hazards group as flammable, corrosive, or toxic. Workers need to understand the meanings of these symbols to recognize and respond to potential hazards in the workplace.

GHS Hazard Classes and Categories

The GHS system includes several hazard classes and categories to classify hazardous products based on their specific hazards. Some key hazard classes include flammable liquids, corrosive materials, toxic substances, and ecological hazards. Each hazard class is further divided into different categories that provide more specific information about the nature and severity of the threats. The GHS system helps users identify and manage the risks associated with varying chemicals by classifying chemicals into these major hazard groups, classes, and categories.

GHS Criteria For The Different Hazard Classes

The GHS establishes specific criteria for each hazard class to ensure consistent and accurate hazard classification. These criteria consider the hazardous products' physical, occupational health, and environmental hazards and guide how to assess and classify them. By applying these criteria, businesses can determine the appropriate hazard class and category for their hazardous products, allowing for effective hazard communication and risk management.

GHS Labelling Requirements

The GHS system has specific labeling requirements to identify hazardous materials and communicate their hazards effectively. Labels must include the most hazardous product, identifier, supplier information, hazard pictograms, signal words, hazard statements, and precautionary statements. Standard GHS pictograms and hazard statements help workers quickly recognize the hazards associated with a hazardous product and take appropriate precautions to ensure safety.

Safety Data Sheets (SDS) and Their Importance

Safety Data Sheets (SDS) are essential to the GHS system. SDS provides detailed information about a chemical's hazards, handling, storage, and emergency procedures. They also include information on the composition of the hazardous product, first aid, appropriate control measures used, and regulatory information. SDS are crucial for ensuring that workers have access to comprehensive and accurate information about the hazards associated with the hazardous products they work with, allowing them to take appropriate safety measures.

What are the suppliers' duties under GHS?

Under Workplace Hazardous Materials Information System (WHMIS) 2015, suppliers must ensure that hazardous products and materials are correctly labeled and accompanied by accurate safety data sheets. Suppliers must classify their products according to the GHS classes and categories, provide appropriate labels with GHS pictograms and hazard statements, and ensure that each safety data sheet is readily accessible to customers.

Suppliers play a crucial role in safely handling and using hazardous materials by fulfilling these duties.

What happens when an inspector visits the workplace?

When an inspector visits a workplace to assess compliance with WHMIS 2015 regulations, they will typically review the company's hazard communication program, inspect the labeling of hazardous materials, and check the availability and accuracy of safety data sheets. Inspectors may also interview employees to assess their knowledge and understanding of WHMIS 2015 requirements. If any deficiencies or non-compliance issues are identified, the inspector may issue warnings, fines, or other penalties, depending on the severity of the violations.

GHS Resources and Tools

Several resources and tools are available to help businesses navigate the GHS system and ensure compliance. Health Canada provides comprehensive guidance documents, fact sheets, and online resources that explain the requirements of WHMIS 2015. Industry associations and training providers offer specialized WHMIS training programs and tools to help businesses implement GHS in their workplaces. Additionally, online platforms provide convenient access to GHS-related training courses and materials, allowing companies to train their employees efficiently and effectively.

Conclusion: GHS Compliance is a Legal Requirement

Understanding and navigating the GHS is crucial for businesses that work with hazardous materials in Canada. By adopting the core elements of the GHS, such as hazard groups, hazard classes and categories, labeling, and safety data sheets, companies can improve hazard communication and ensure the safe use and handling of hazardous products.

Safety training compliance with GHS regulations is not only a legal requirement but also a moral responsibility to protect the health and safety of workers.

For more information, please contact us to inquire about our Health and Safety training.